How the manufacturing of the Kaaba cover, kiswa, changed over the centuries

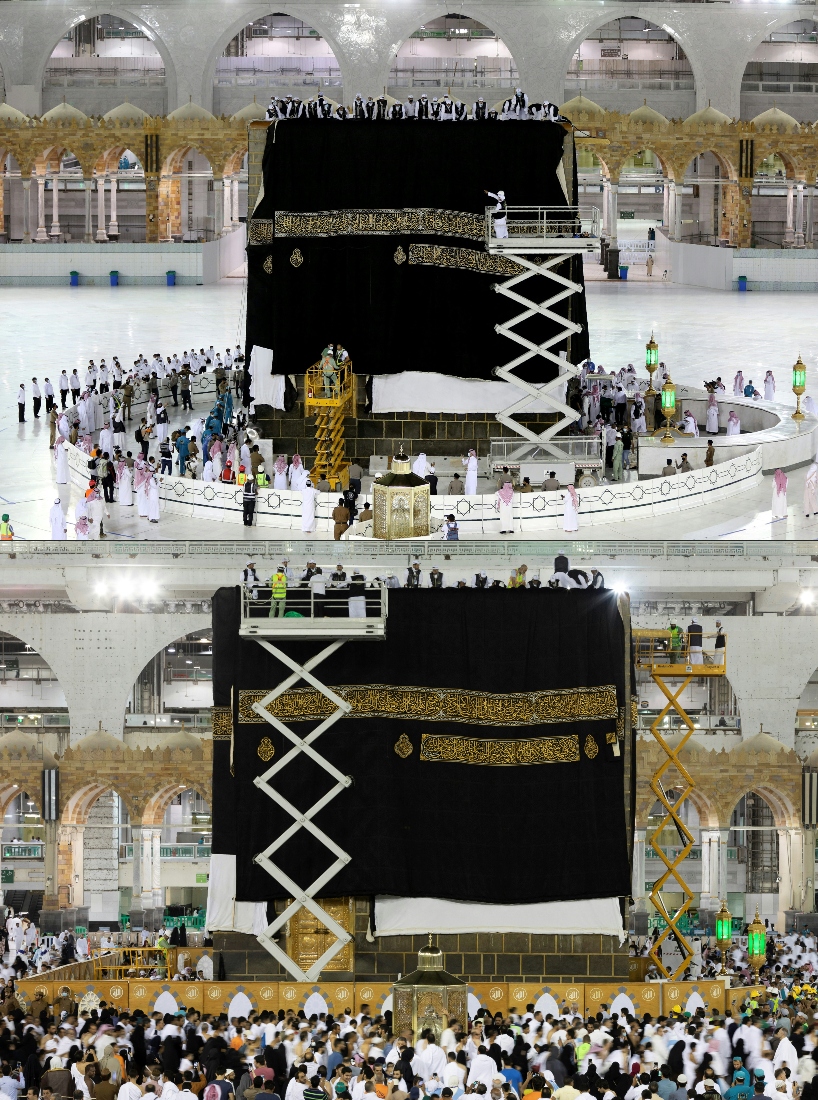

Every year on the ninth or tenth day of Dhul Al-Hijja, the 12th and final month of the Islamic calendar, the holy Kaaba is adorned with a new covering (kiswa) to mark the occasion of Eid Al-Adha.

Abdulhamid bin Said Al-Maliki, the deputy general president for affairs at the King Abdulaziz Complex for Manufacturing the Kaaba Kiswa, said the new kiswa would be draped over the Kaaba on the first day of Muharram instead of the ninth day of Dhul Al-Hijja, marking the beginning of the new Islamic year.

Making the kiswa is no easy feat. Skilled workers and technicians put in hours to precisely and immaculately create and embroider the kiswa to cover the Kaaba, which is a focal point for Muslims around the world throughout the year.

Arab News went on a tour of the King Abdulaziz Complex for Manufacturing the Kaaba Kiswa in Makkah to witness the fabrication of the kiswa firsthand.

The 100,000-square meter complex was previously known as the Kiswa Factory, which was established in 1928. Its name was changed to the King Abdulaziz Complex for Manufacturing the Kaaba Kiswa in memory of King Abdulaziz, the founder of Saudi Arabia, following a royal decree from King Salman in 2017.

Al-Maliki said the complex had witnessed many developments, such as moving from traditional manual work to an automated system.

The kiswa is made from scratch at the complex, starting by procuring silk and cotton threads that are tested in its laboratory for quality.

These threads are dyed and woven into the cloth with the help of high-end machines. After this process, the fabric undergoes vigorous physical tests to ensure its strength and durability to withstand all kinds of environmental factors throughout the year.

Ahmed Al-Sulami, a quality analyst at the laboratory, said: “We are testing the tensile (strength) and elongation and the effect of light on the dyes. The tensile strength must be more than a thousand-kilo force.”

The 658 square-meter kiswa is made from 670 kilos of black silk. It consists of 47 silk pieces stitched together by special machines.

“The sides of the Kaaba are not equal and are not considered a cube of symmetrical lengths. Each side of the Kaaba cube features a different length and width,” said Salman Al-Luqman, who has been head of the textile department at the complex for around 40 years.

The kiswa features the names and attributes of Allah: Ya Allah, Ya Mannan, Ya Dayyan, Subhanallahi Wa Bihamdihi Subhanallahil Azeem, and La ilaha illallah Muhammadur Rasulullah.

Al-Luqman told Arab News: “In the first stage, the threads are wound on bobbins of the required length. After that, the warping process takes place, in which the threads are collected and transferred to the weaving machine that works with the jacquard machine, which is the secret behind the texts woven on the black silk fabric.”

The automated weaving department also manufactures the Ihram, white cotton that covers the kiswa when it is lifted by around 3 meters from the bottom during the beginning of the Hajj season.

The kiswa then moves to the gilding and embroidery department, where the beautiful golden belts around the Kaaba and the curtain of the door are handmade with precision.

Sami Muzayyan, the department supervisor of kiswa gilding and embroidery, told Arab News that over 50 skilled artisans and embroiderers, aged between 23 and 60, hand embroidered verses from the Holy Qur’an and other prayers with 100 kilos of pure silver and 120 kilos of 21-karat gold-coated silver threads on 56 different pieces of silk.

Muzayyan said: “The wires are not made of pure gold because if so, it won’t be flexible enough. Rather it is made of gold-coated silver of German manufacture featuring a good level of flexibility to ease the procedure. The texts on the Kaaba are printed first according to the established manuscripts in Thuluth (a type of Islamic calligraphy) created by the previous Kaaba calligrapher Abdulrahim Amin Bukhari.”

The Kaaba door is made of five connecting curtains featuring different Qur’anic verses and three complete surahs: Al-Fatiha, Al-Falaq and An Nas, and Quraysh.

In addition to the golden belt, the kiswa has 17 qandeels, lamp-shaped medallions with each featuring a name of Allah: Ya Hayyu Ya Qayyum, Allahu Akbar, Ya Rahman Ya Rahim.

He said that the embroiderers used manasij, a traditional wooden hoop.

The white fabric is pulled between them before laying pieces of black silk on top. It is then tightened so that workers can do their embroidery. To give the embroidery texture, the letters are filled with cotton threads before being covered with gold and silver.

The kiswa is distinguished by three things: “Makkah Al-Mukarramah” embroidered in Arabic, the year in which it will be used, and the name of the reigning king.

It takes eight to 10 months to finish all the embroidery. Once completed, the silk pieces are collected, stitched together, and gilded. All parts of the kiswa are stored in special warehouses at the General Presidency for the Affairs of the Two Holy Mosques and can be used only after permission from King Salman and Crown Prince Mohammed bin Salman.

The complex will soon become a cultural attraction and create more job opportunities.

“We are working closely with the general president of the complex Dr. Abdulrahman Al-Sudais to develop programs, initiatives, and projects which will result in making the complex a cultural landmark and a point of attraction for all those coming to Makkah, so visitors from all over the world can enjoy a rich experience,” Al-Malki said.

The complex is working on using artificial intelligence to enrich the visitor experience through robots that will assist visitors in different languages by explaining the origin of the kiswa, the choice of Qur’anic verses, and calligraphy.

Al-Maliki also said that some initiatives would focus on women’s empowerment and training Saudi women to participate in the manufacture and embroidery of the kiswa in the future.

The complex will also soon launch a restoration center, where different pieces of the kiswa can be restored.